Facing problems with industrial wastewater disposal?

Industrial wastewater often contains harmful chemicals, oils, heavy metals, dyes, and organic matter that cannot be released directly into the environment.

An Effluent Treatment Plant (ETP) is designed to treat and purify industrial effluent to meet Pollution Control Board (PCB) discharge standards — ensuring both environmental safety and legal compliance.

Whether you run a manufacturing unit, textile dyeing plant, food processing unit, or pharmaceutical industry, an ETP is essential for treating wastewater before it is reused or safely discharged.

Over 80% of industrial wastewater globally is discharged untreated — leading to severe soil and water contamination.

Our Solution

Features | Other Companies | Our Company |

|---|---|---|

Types of Filter Media | Limited | All types of available media |

Warranty | 1 year | 1 year |

Budget | Fixed | Flexible |

Media Layers | Average | Expert technicians for the most efficient media layering |

Customization | Limited | As per our client's requirement |

Support | Working days and hours only | On call support through 4 lines |

Brand Options | Limited | All leading manufacturing brands |

Key Features

-

Multi-stage treatment process for maximum purification efficiency.

-

Removes suspended solids, BOD, COD, oil & grease, and heavy metals.

-

Automated control panel for easy operation and monitoring.

-

Compact FRP/MS construction — corrosion-resistant and durable.

-

Modular design suitable for expansions or increased load.

-

Optional Electrocoagulation (EC) Technology for advanced treatment.

-

Meets CPCB and SPCB discharge norms.

-

Reduces water consumption through recycling and reuse.

-

Protects soil and groundwater from contamination.

-

Decreases operational cost over time with efficient recovery systems.

-

Enhances corporate environmental compliance and sustainability.

Benefits

Applications

Removes color, dyes, and high-COD organic matter.

Treats oily and organic wastewater.

Handles toxic and non-biodegradable pollutants.

Removes oil, grease, and heavy metals.

Reduces high suspended solids and organic load.

Working Principle

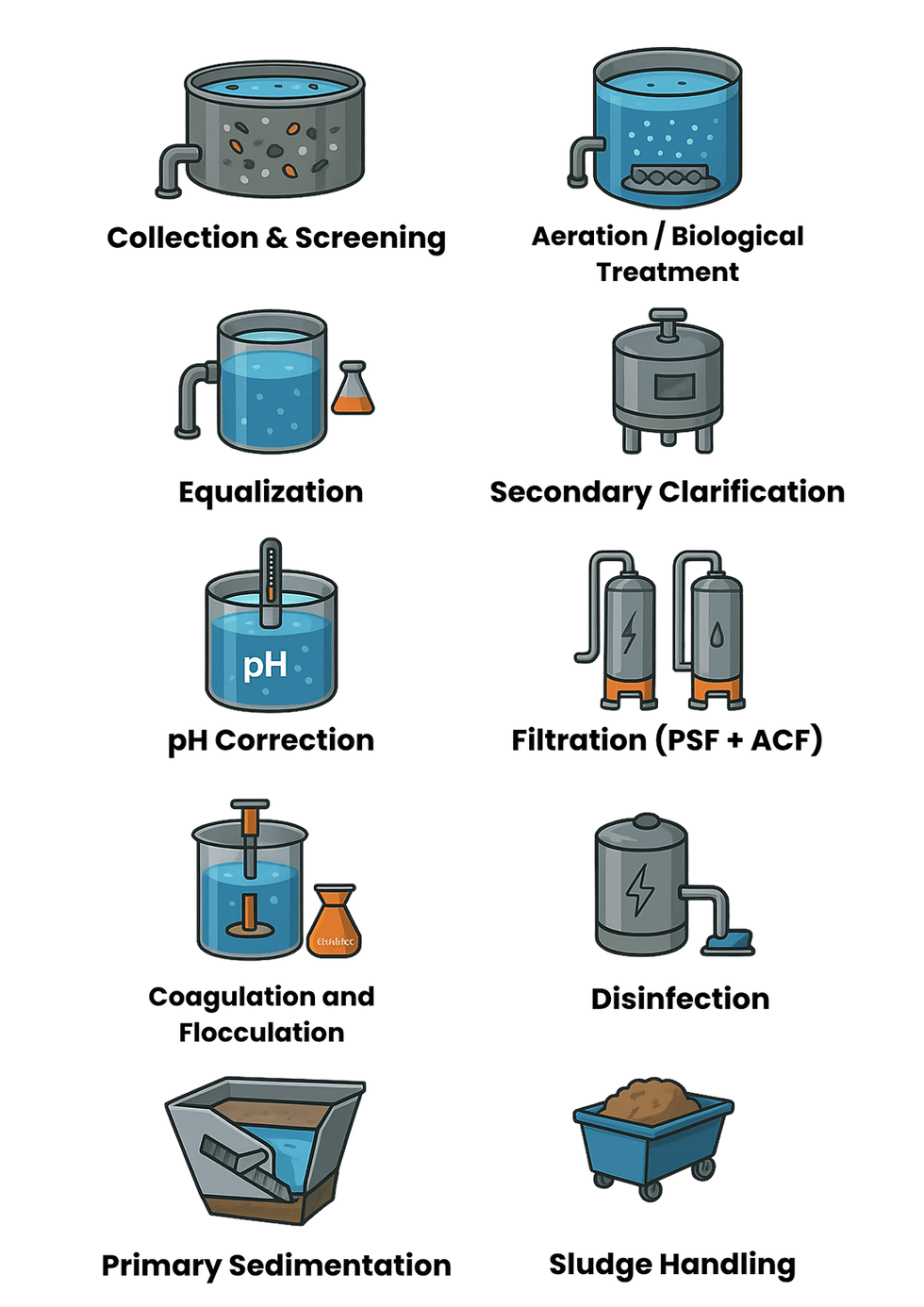

-

Collection & Screening:

Effluent from production areas enters the collection tank; screens remove plastics, fibers, and debris. -

Equalization:

The flow and load of wastewater are balanced to ensure consistent treatment efficiency. -

pH Correction:

Acidic or alkaline wastewater is neutralized using dosing of lime or acid to bring pH between 6.5–8.5. -

Coagulation & Flocculation:

Coagulants (like alum or PAC) and flocculants are dosed to form larger flocs that settle easily. -

Primary Sedimentation:

Heavy solids settle at the bottom; clarified water moves forward. -

Aeration / Biological Treatment:

In this tank, air is diffused to promote bacterial growth which consumes organic pollutants (reducing BOD/COD). -

Secondary Clarification:

Sludge from biological treatment settles and is recycled or dewatered. -

Filtration (PSF + ACF):

Pressure sand filter removes fine particles; activated carbon filter removes odor and color. -

Disinfection:

Treated water is disinfected using chlorine, ozone, or UV before storage. -

Sludge Handling:

The settled sludge is pumped to sludge drying beds or filter press, and dried sludge is disposed of safely.

Sections of an Effluent Treatment Plant

Collection & Screening Tank

Collects raw effluent and removes large debris.

Equalization Tank

Balances flow and pollutant load before treatment.

pH Correction / Neutralization Tank

Adjusts acidity or alkalinity for optimum treatment.

Coagulation & Flocculation Tank

Adds coagulants (e.g., alum, PAC) to bind fine particles.

Primary Clarifier

Settles heavy solids for removal.

Aeration Tank (Biological Treatment)

Uses aeration blowers to degrade organic matter (BOD/COD).

Secondary Clarifier

-

Separates biological sludge from treated water.

Filter Feed Tank & Pressure Sand Filter (PSF)

Removes suspended solids.

Activated Carbon Filter (ACF)

Removes odor, color, and residual organics.

Sludge Handling System

Includes sludge drying beds or filter press for solid disposal.

Treated Water Tank

Collects clean water for reuse or safe discharge.

How to Operate

-

Ensure raw effluent collection tanks are filled.

-

Turn ON the control panel and feed pumps.

-

Dose pH correction and coagulant chemicals as per readings.

-

Operate aeration blowers to maintain DO between 2–4 mg/L.

-

Monitor pH, BOD, and COD periodically.

-

Backwash filters and clean tanks daily.

-

Dispose of sludge periodically through drying beds or filter press.

Maintenance Guide

-

Clean equalization and clarifier tanks every month.

-

Backwash PSF & ACF daily for efficient filtration.

-

Replace carbon media every 6–12 months.

-

Inspect pumps, valves, and blowers weekly.

-

Calibrate dosing pumps regularly.

Pro Tips for Long-Term Performance

-

Maintain consistent flow to prevent shock load on the system.

-

Avoid overdosing chemicals — it increases sludge volume.

-

Keep pH in range 6.5–8.5 for biological treatment.

-

Use energy-efficient blowers for aeration.

-

Schedule quarterly preventive maintenance checks.

Ready to make your industry eco-compliant?

Contact us today for a customized Effluent Treatment Plant designed to meet your flow, space, and discharge standards.

Let’s build a cleaner future — one drop at a time.

Suggestion: Our Advanced Tech – Electrocoagulation ETP

Upgrade to our Electrocoagulation (EC) ETP, which replaces traditional chemical coagulation with an electrical current-based process.

This advanced system offers:

-

60–70% lower chemical usage.

-

Compact design with faster treatment.

-

Effective removal of color, heavy metals, and oil.

-

Reduced sludge generation and operating cost.

Ideal for pharma, dyeing, plating, and food industries where consistent effluent quality is critical.

Comprehensive Solutions for any type of Water

Water containing excess dissolved iron, causing rust stains and metallic taste.